In the heart of Lincolnshire’s diverse industrial landscape—from manufacturing plants in Lincoln to agricultural facilities in the Wolds and food processing units in Spalding—electric motors form the backbone of operations. These workhorses power pumps, conveyors, fans, and machinery essential for daily productivity. However, like any critical component, they require regular attention to ensure safety, efficiency, and longevity. At Matson Electrical Services Ltd., with over 15 years of experience serving Lincolnshire’s industrial, commercial, and agricultural sectors, we’ve seen firsthand how proactive motor inspections can prevent costly disruptions and enhance overall system performance.

Understanding and Setting Electric Motor Inspection Tasks

Electric motors are ubiquitous in UK industries, accounting for a significant portion of energy consumption. Poorly maintained motors can waste energy, leading to higher operational costs and increased carbon footprints. Regular inspections not only identify potential issues early but also align with health and safety regulations, helping businesses avoid fines and downtime. In this article, we’ll explore what these inspections entail, their benefits, and how they fit into broader electrical maintenance strategies.

Table of Contents

Understanding Electrical Motor Inspections

An electrical motor inspection is a systematic evaluation designed to assess the condition and performance of motors in industrial environments. Typically conducted quarterly or based on usage and environmental factors, these checks combine visual assessments, electrical testing, and mechanical evaluations to ensure compliance with standards like BS EN 60034 for rotating electrical machines.

The process begins with motor identification, noting details such as the tag number, location, manufacturer (e.g., SEW Eurodrive), rating (like 0.75kW, 400V three-phase), and voltage/frequency specifications. This foundational step ensures the inspection is tailored to the specific equipment.

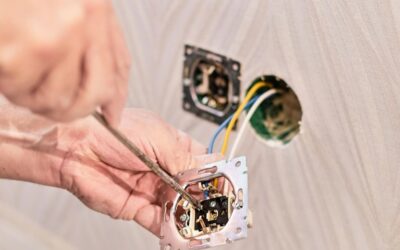

Next comes the visual inspection. Technicians examine checkpoints for signs of wear: no cuts or abrasions on cables, secure glands and terminations, clean and corrosion-free connections, crack-free motor housings, good condition of cooling fans and guards, and intact nameplates. Minor issues, such as slight dust ingress or bearing judder, are noted but may not immediately halt operations if they don’t pose risks.

Electrical testing follows, measuring parameters against acceptable ranges. This includes supply voltages (within ±10% of rated), phase balance (≤2% preferred), running currents (within nameplate ratings), insulation resistance (>1MΩ, often tested at 500V), and earth continuity (<0.5Ω). For instance, a passing insulation resistance of over 150MΩ and low earth resistance of 0.1Ω indicate robust electrical integrity. These tests help detect faults like insulation breakdown or poor grounding, which could lead to fires or shocks.

A condition assessment rates aspects like visual condition, electrical readings, and mechanical factors (noise, vibration, bearings) on a red-amber-green scale. An overall amber rating might signal wear from water ingress or dust, prompting recommendations without immediate shutdown. Finally, actions and recommendations outline steps like cleaning, lubrication, or repairs to maintain optimal function.

Motor Testing: An Overview | Reliable Plant

The Benefits of Routine Inspections

The advantages of regular motor inspections extend beyond mere compliance. Firstly, they enhance safety by identifying hazards early, reducing the risk of electrical fires—a major concern in industrial settings where faulty wiring contributes to incidents. In the UK, the Health and Safety Executive (HSE) emphasizes risk assessments and proper maintenance for electrically powered equipment to prevent accidents.

Efficiency gains are equally compelling. Well-maintained motors operate closer to their rated performance, minimizing energy waste. Studies show that regular maintenance can extend equipment lifespan by preventing breakdowns and optimizing performance, potentially saving businesses thousands in replacement costs. For Lincolnshire’s agriculture and manufacturing sectors, where motors drive irrigation pumps or conveyor systems, this translates to uninterrupted production during peak seasons.

Moreover, inspections help mitigate costly downtime. A failed motor in a food processing line could halt operations for hours or days, impacting revenue. By scheduling flexible inspections tailored to the motor’s criticality and environment—such as more frequent checks in dusty or humid conditions—facilities can proactively address issues. This approach also supports sustainability goals, as efficient motors reduce carbon emissions, aligning with the UK’s net-zero ambitions.

Compliance and Standards in the UK

In the UK, electrical inspections are governed by regulations like the Electricity at Work Regulations 1989, which mandate safe systems to prevent danger. For commercial and industrial sites, periodic inspections ensure adherence to BS 7671 (IET Wiring Regulations). Motor testing falls under this umbrella, with recommendations for inspections based on usage—every 3-6 months for high-duty motors.

Non-compliance can result in legal repercussions, insurance voids, or operational halts. Engineering inspections, including those for motors, are crucial for ongoing safety and suitability, as highlighted by industry experts. In Lincolnshire, where industries range from coastal operations in Skegness to inland factories in Boston, local factors like humidity or dust necessitate vigilant maintenance.

A Real-World Example from Lincolnshire

Consider a recent inspection we conducted on a liquid filler pump motor in an industrial facility. The SEW Eurodrive unit showed minor visual wear, including dust on the housing and slight bearing noise, but passed electrical tests with flying colors—insulation resistance at 150MΩ and balanced currents. Rated amber overall, recommendations included cleaning and monitoring to prevent escalation. This proactive step averted potential failure, ensuring the facility’s compliance and smooth operations.

Such examples underscore how inspections integrate with comprehensive services. For instance, while focusing on motors, we often incorporate Electrical Installation Condition Reports (EICRs) to evaluate the entire system every five years or upon tenancy changes, identifying broader hazards. Upgrading outdated fuse boards to modern consumer units enhances safety for high-power industrial loads, preventing overloads that could affect motors.

As industries evolve, incorporating electric vehicle (EV) chargers becomes relevant. In Lincolnshire’s rural and urban sites, installing EV chargers for fleet vehicles requires robust electrical infrastructure, where motor inspections ensure compatibility and efficiency. Our NICEIC-approved team handles these seamlessly, from Sleaford to Grimsby.

Industrial Motor Monitoring | Dynamic Ratings

Conclusion: Prioritizing Maintenance for Long-Term Success

Regular electrical motor inspections are more than a regulatory checkbox—they’re an investment in safety, efficiency, and sustainability for Lincolnshire’s industries. By addressing issues early, businesses can extend equipment life, reduce energy costs, and maintain compliance. At Matson Electrical Services Ltd., our experienced electricians provide tailored inspections, drawing on accreditations like NAPIT and CHAS to deliver reliable results.

If your facility in Lincoln, Woodhall Spa, or beyond relies on electric motors, consider scheduling a professional assessment. Contact us at 07342 039 023 or matsonelectrical@gmail.com to discuss how we can support your electrical needs. Staying ahead with maintenance ensures your operations run smoothly, today and tomorrow.